Laser engraving allows us to create things that would be practically impossible using other mediums, offering an unmatched level of consistency, speed and detail. But with that said, what goes into a typical laser engraving project, and what do you have to look forward to when planning out your own?

At Vector and Raster, we have worked on thousands of laser engraving & laser cutting projects for creators and businesses across Australia and beyond. So, without further ado, let’s take a look at the engraving process from planning to the finished product.

What is Laser Engraving?

Terms such as engraving, etching, marking can sometimes be confusing to people. However, in the end, they can all relate to the same thing: The process of permanently “printing” text, logos, images directly to the material or product provided. However, there are subtle differences between the three terms:

Engraving

Laser engraving usually relates to a deeper finish in the artwork, like on wood, acrylic, plastic, rubber etc.

Etching

Laser etching relates to lightly removing surface material as can be seen with anodised aluminium, paper, stone, painted and coated finishes, glass etc.

Marking

The term laser marking tends to get used when applying graphics directly to the surface of a material, such as stainless steel, raw aluminium, or brass. At the end of it all, we’ll know what you mean and will assist in helping achieve your vision.

At VR Laser we always aim to leave the engraved product spotless, either requiring no or very little attention before using the engraved item. This not only makes the finished product much more appealing but can also minimise the cost of having to clean and finish the product off with a secondary process.

So, now that we know the terminology, how do we start the process?

The Creative Spark

As with most artistic endeavours, it all starts with a creative mind. The client supplies a file with what they envision as the ideal piece for their application. From there, they can begin to describe the finer details of their project and any specific requirements they may have. Many often question whether what they want is even possible, or aren’t sure what material to use. We are able to advise on whether the concept will work or whether tweaks need to be made to achieve the required results.

Once these details are ironed out, we can begin building the file that our machines will work from.

Creating the Blueprint

Ultimately, a vector file (CAD) is required to process the engraved work on the laser machines. This is essentially the blueprint our machines use to work out exactly what you want and how to achieve it.

Obviously, many of our clients aren’t overly familiar with the file-creation process. If this applies to you, don’t worry, as we can assist in creating the correct engraving files if need be. Preferred files for engraving include EPS, CDR, AI, PDF, SVG, DXF and DWG.

Linework and Marking

Areas to be ‘marked’ by the laser should have a solid black fill for solid marking or an outline that is at least 0.2mm or wider for ‘marked’ line work. Vector etching may also be possible for thin linework on some materials, which is normally identified on files as a hairline or .001mm stroke Cyan outline.

Ideally, all colours should be in RGB values and all elements of the same nature should be grouped. This allows us to make changes to the file easily if and when it is required.

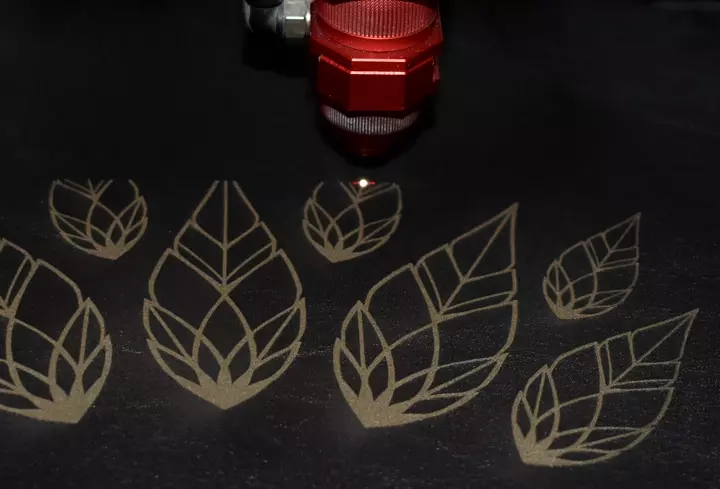

The Engraving Commences

During the laser engraving process, the laser creates an extremely high level of heat, effectively vaporising off layers of the material, and creating images using the freshly-exposed cavities created. This process is very quick, as vaporisation occurs with every pulse. To make deeper engraving marks, areas can be moved over again and again to get the precise level of depth required.

~

And there you have it. Once your engraving is complete, we will check it to ensure that your design has been achieved perfectly. From there, the process can be repeated as many times as necessary, and what you end up doing with your finished product is entirely up to you! To find out more about what we can do for your next project, contact Vector & Raster and speak with the experts today!