When it comes to laser cut acrylic, there is no company more suited to the job than V&R Laser. Acrylic plastic is a highly versatile material that is widely used in an extensive variety of products, from consumer electronics and vehicles to everyday products and much more. Also commonly referred to as Perspex, it’s a material that is favoured for its durability, strength, weather resistance and ability to maintain its colour. Clear acrylic sheets are renowned for their superior optical clarity and resistance to ultraviolet light. With our laser cutting services, acrylic is a known and highly popular choice for manufacturing signs, point-of-sale displays, visual merchandising and a whole range of other products.

Vector & Raster Laser Services specialises in custom laser cut acrylic, ensuring that whether you’re a commercial client or a DIY-er off the street completing a project, we’ll cut exactly what you need.

Hit the button and tell us about your next project for your free quote.

LET'S GET STARTED

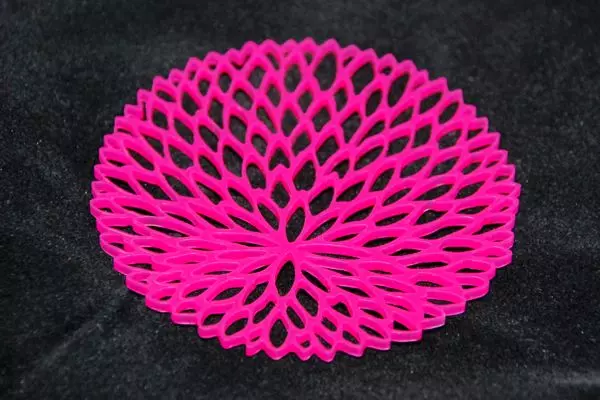

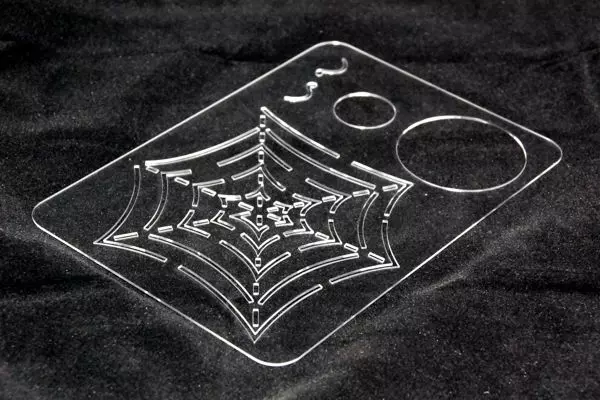

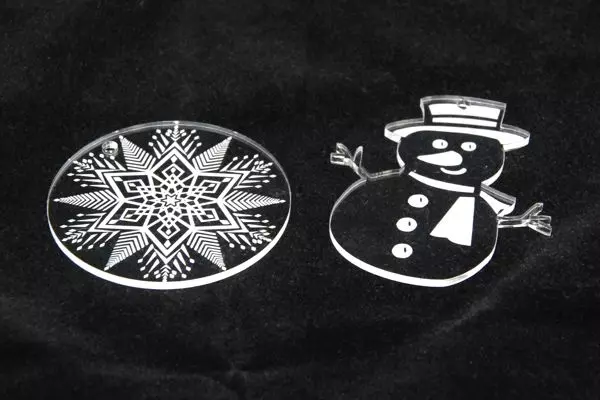

Laser cut acrylic is well known for its lovely flame polished edge. With any job processed on our acrylic laser cutter, we’re able to achieve this quality edge as well as extremely high detailed and crisp laser engraving. Acrylic is available in a variety of thicknesses, finishes and also comes in a huge range of stunning colours. It is commonly used in craft applications such as ornaments, jewellery, invitations, swing tags and more. Whether it’s custom wedding decor, keychains, or layered wall art, our expert craftsmanship brings your visions to life. Discover the beauty of acrylic through mirror-like finishes and unique designs.

Furthermore, it is also widely used in signage, logos, displays, architectural models and many other applications. We want you to experience efficiency and affordability as your projects evolve into stunning acrylic designs.

For the best and most professional acrylic laser cutting, there’s only one name to turn to: Vector & Raster Laser Services. We can provide custom laser cut acrylic products to suit your specific needs and requirements. If you’d like further information about laser cut acrylic / Perspex or our laser cutting in Melbourne, give us a call at (03) 5783 4257. Alternatively, you can also request a quote online.

Hit the button and tell us about your next project for your free quote.

About Us

When it comes to our Melbourne laser cutting service, we pride ourselves on high-quality workmanship. Our philosophy is simple, with all things laser cutting and laser engraving, we provide top quality results and customer service that simply rocks! Our Melbourne based laser cutters can be used for a wide range of applications.

Can you laser cut acrylic?

Acrylic, or Perspex, is one of the best materials for cutting. Laser cut acrylic produces high-quality, polished looks of your design. Cutting laser acrylic transforms your intricate designs into a sleek, precise creation. Acrylic is durable, UV resistant and high in clarity. As such, this method is perfect for making signs, sale displays, visual merchandising and more. At V&R Laser, we specialise in acrylic sheets. Talk to one of our professional staff today to get a free quote.

What do you need to laser cut acrylic?

At its basics, we require a vector file with your design of choice. We have state-of-the-art laser machines and can supply the acrylic sheets. The laser heats and vaporises sections of the material to create various shapes. Our leading machines are optimised to cut acrylic without damaging the material. Our cutting services require a high level of expertise because insufficient knowledge can lead to material damage. That is why it is always best to get your design cut by our experts.

How strong of a laser do you need to cut acrylic?

This is variable, but as a fundamental guide, it is generally 10W for every millimetre of acrylic sheet. Our top-quality machines can cut all kinds of acrylic sheets with varying thickness. Generally, the more power the machine has, the more efficient the process becomes and the better the quality of the cut. Please speak to one of our experts today to discuss how we can suit your needs and requirements.

Is Perspex the same as acrylic?

Perspex is the brand name for premium acrylic sheets. Not all acrylic sheets are created equal and some poor quality sheets are subject to weathering and ageing. We like working with Perspex due to its high quality, but also stock other quality acrylic sheets that are more than suitable for most jobs. Perspex sheets vary in thickness, colour and finishings to suit your requirements. Any Perspex sheet is recyclable, weather resistant, easy to clean and very durable.

Can I have a quote over the phone?

Sorry, but we cannot provide a quote over the phone, laser engraving and cutting prices can vary dramatically based on the design and material being processed, we require artwork to provide an accurate quote.

Can you create the correct artwork for me?

Yes, if you are unable to provide the required artwork for processing your order we can create the files for you no matter what process you intend on using whether it be laser engraving or cutting.

What type of files do you require?

We require a vector file which has been created in a graphics program, acceptable types include eps, cdr, ai, dxf, dwg and pdf. Cut lines should consist of a red outline with no fill using a .001mm stroke width, areas to be engraved should be in black fill. Only photographs will be accepted as a high resolution jpeg or bitmap.

Can I supply my own materials?

Yes, if you prefer to supply your own materials we are happy to process them for you providing that they are suited to the laser process, a test sample is recommended for perfect results when processing your order.

Hit the button and tell us about your next project for your free quote.