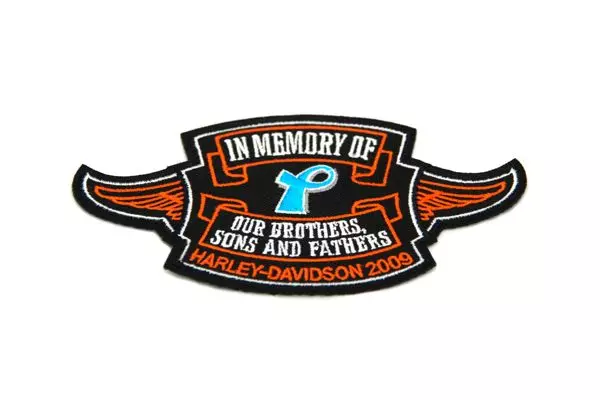

Our embroidery applique cutting service has been widely used by some of Australia’s largest embroiderers for many years now on a regular basis, we cater for all quantities ranging from sample garments to large production runs. A selection of the most popular fabrics that have been used for embroidery appliqué cutting over the years includes cotton drill, polyester felt, fused satin, acrylic moss stitch, denim, fleece fabric, modern design and many other bright and amazingly textured fabrics.

In addition to providing laser cutting, laser cut fabric and laser etching, our embroidery applique services can be applied to materials such as denim, fleece and leather and have also proved to be a popular way of adding interest and distinction to products such as pockets, belts, bags, shoes, wallets and many other textiles.

Hit the button and tell us about your next project for your free quote.

LET'S GET STARTED

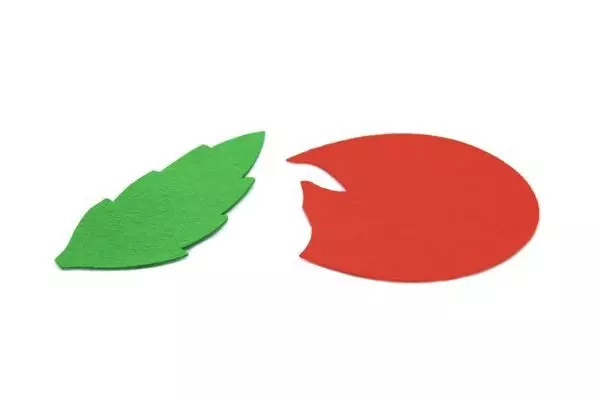

Embroidery appliqué cutting is defined as a design that is digitised so that it incorporates a laser cut piece of fabric known as appliqué and is then combined with embroidery to achieve an eye-catching design that really “pops”. Embroidery applique cutting is commonly used on garments such as laces, sportswear, kids’ clothing, university hoodies, fashion garments, cloth fabrics and even caps and other headwear. Vector & Raster Laser Services can provide embroidery appliqué for all types of clothing, so no matter what design you want to add you can create your perfect design.

To obtain a FREE no-obligation quote online for our embroidery applique cutting service, then simply use our ‘Get Quote‘ tool or contact us at (03) 5783 4257.

Hit the button and tell us about your next project for your free quote.

About Us

When it comes to our Melbourne laser cutting service, we pride ourselves on high-quality workmanship. Our philosophy is simple, with all things laser cutting and laser engraving, we provide top quality results and customer service that simply rocks! Our Melbourne based laser cutters can be used for a wide range of applications.

Can I have a quote over the phone?

Sorry but we cannot provide a quote over the phone, laser cutting and laser engraving prices can vary dramatically based on the design and material being processed, we require artwork to provide an accurate quote.

Can you create the correct artwork for me?

Yes, if you are unable to provide the required artwork for processing your order we can create the files for you no matter what process you intend on using whether it be laser cutting or laser engraving.

What type of files do you require?

We require a vector file which has been created in a graphics program, acceptable types include eps, cdr, ai, dxf, dwg and pdf. Cut lines should consist of a red outline with no fill using a .001mm stroke width, areas to be engraved should be in black fill. Only photographs will be accepted as a high resolution jpeg or bitmap.

Can I supply my own materials?

Yes, if you prefer to supply your own materials we are happy to process them for you providing that they are suited to the laser process, a test sample is recommended for perfect results when processing your order.

How do you cut embroidery appliqué?

Embroidery applique cutting is a fairly simple process. Most commonly, the fabric is cut with a specialised cutting machine. The most popular type of cutting machine is a laser cutter, which can cut intricate shapes with precision. The embroidery fabric to be cut is placed on a cutting bed, and the design is programmed into the machine. The laser then cuts out the pattern with very little waste material. This process is accurate, and efficient and can be used to make small and large appliqué pieces.

How do you turn an embroidery design into an appliqué?

Turning an embroidery design into an appliqué can be followed by a straightforward approach. First, you must create a design file using a vector-based software program like Adobe Illustrator. This design file can then be imported into a cutting machine, such as a laser cutter. We can then cut the fabric pieces to the exact shape and size of the design. The embroidery applique cutting pieces can then be sewn onto a garment or other item to create the appliqué. If your design has been digitised in embroidery software, we will require the running stitch in an EPS format.

How do you stop appliqué edges from fraying?

Stopping appliqué edges from fraying can be done by applying a fabric adhesive or fusible web to the back of the fabric before cutting the appliqué pieces. This adhesive or web will help to hold the edges of the fabric pieces together and reduce the chance of them fraying, as well as giving the cut applique pieces some stability, making them easier to work with. In general, synthetic fabrics will have a much stronger sealed edge once laser cut, as the heat, will fuse the edge during the cutting process. Natural fibres on the other hand will benefit from having a satin stitch or similar applied during the embroidery process.

How do you cut appliqué shapes?

At Vector & Raster Laser, we use laser cutting to cut embroidery appliqué pieces. Laser cutting is the most efficient and accurate method available and it provides a consistent, high-quality result.

Machine choice can depend on whether the fabric or leather requires more power or a vacuum table, or if it is a sensitive fabric that may benefit from a lower-powered machine with a finer lens choice to create a thinner cutting beam.

What are the disadvantages of applique?

The main disadvantage of applique is that it is time-consuming and complex designs are not possible to be achieved by hand. Furthermore, the labour intensiveness to cut a multitude of units by hand would be impossible and lessen its value for accurate or identical pieces. Laser cutting, however, is much faster, and more efficient, adding accuracy and repeatability for larger runs.

The heat seals the edges to avoid fraying and is economical as we can nest the pieces close together, avoiding the wastage of fabric. Applique provides an eye-catching look that cannot be produced any other way. It also reduces the amount of stitching required on large designs.

Hit the button and tell us about your next project for your free quote.