While it may seem like a modern invention, laser cutting methods have had a considerable history. As a matter of fact, lasers have been part of material processing since the mid-60s, with the method in which these lasers are used being refined ever since. That said, while laser cutting methods are used in practically every facet of the manufacturing world, from fashion design to the automotive world, they aren’t necessarily well understood outside of the fact that, well, lasers are used to cut things.

At Vector & Raster, we have spent the better part of two decades providing premium-quality laser cutting services to businesses, designers and individuals across Australia and beyond. So, to help you understand a little bit more about our processes, as well as the processes of the laser cutting world at large, let’s take a slightly technical look at what laser cutting is, how it works, and why it’s so effective.

What is Laser Cutting?

At its core, laser cutting is a thermal process. This means that, through the use of a highly-targeted laser beam, heat is used to melt small slits or kerfs into materials. This focused beam can then create a continuous cut by moving either the material or the laser beam itself to form the desired cut pattern. The advantages of this cutting technology were evident right from its discovery in 1960, with them having a place in diamond mines for their cutting and drilling capabilities as early as 1965 and the aerospace industry by the 1970s.

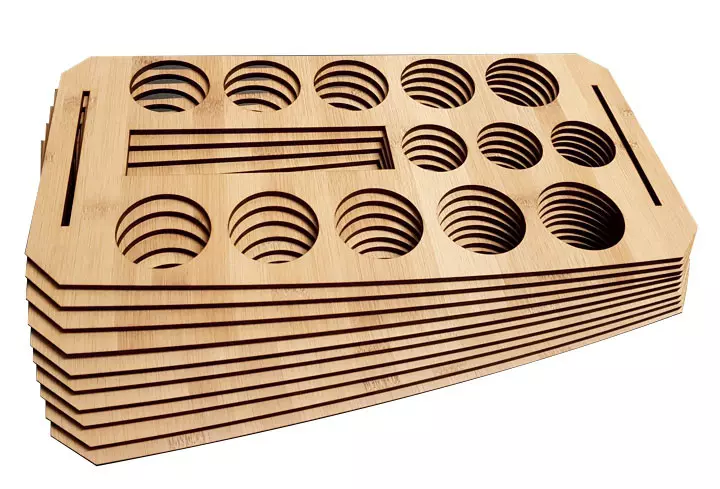

Thanks to the development of numerical control machines (or CNC machines as they are often referred to), laser cutting specialists are able to automate a large portion of this process. This has provided laser cutters with the capabilities needed to create hugely detailed, intricate cuts that simply wouldn’t be possible through traditional means. Advancements in laser cutting methods and technology have also led to laser cutting becoming the most time-efficient option for consistent cutting, etching and engraving, especially on large-scale projects.

Are There Different Types of Laser Cutting Methods?

In most cases, laser cutting methods can be put into three distinct categories:

Fusion Cutting

In this method, molten materials are displaced from the kerf through the use of nitrogen gas (or occasionally other noble gasses). There is no exothermic reaction through the use of nitrogen, meaning that it doesn’t react with the molten materials in the same way that oxygen would.

Remote Cutting

This is primarily used as a means of evaporating materials, which allows for laser cutting without the use of gasses. We at Vector & Raster use the process of vaporisation and evaporation for most non-metal materials, including paper, acrylic, wood, fabric, plastic etc.

Flame Cutting

Similar to fusion cutting, flame cutting uses oxygen instead of nitrogen. This creates a reaction with the molten materials and, in turn, increases the overall energy output of the laser cutting process.

What Makes Laser Cutting Such a Good Option?

As we briefly touched on in a previous point, laser cutting methods have been used since the 60s, and have been benefited a lot by advancements in technology. Today, laser cutting is one of the most versatile, effective manufacturing tools we have, allowing for detailed, precision cutting on the most delicate fabrics, specialised rubber materials and the sturdiest metals alike.

Due to the lack of human error compared to other cutting processes, laser cutting methods are also one of the most economic choices for precision industrial cutting and detailing in regards to cost and time spent. Many of our customers are manufacturers looking for hundreds, even thousands of identical pieces with little to no margin for error, and thanks to our state-of-the-art technology and close to 20 years of experience through this business alone, we can complete these jobs in record time.

~

So, whether you’re looking for intricately detailed business cards, custom-made stencils or finely-detailed industrial parts, we at Vector & Raster have the skills, experience & technology to make it happen. To start your laser cutting journey, contact us today. Alternatively, if you want to learn more about what the laser cutting world has to offer, explore our blog for dozens of articles on everything from laser cutting design to methodologies, and even some festive inspirational ideas along the way.