Looking for a highly experienced precision laser cutting service? Discover the superior quality expertise provided by Vector & Raster Laser Services. We are based in Melbourne and provide quality laser cutting on a broad range of materials Australia-wide. Come and see us for precision laser cutting with excellent edge and surface quality on materials such as:

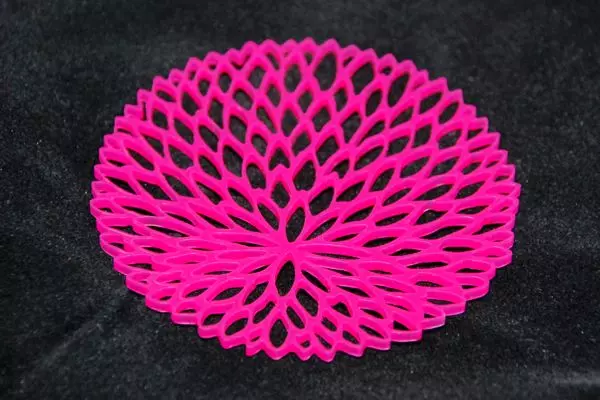

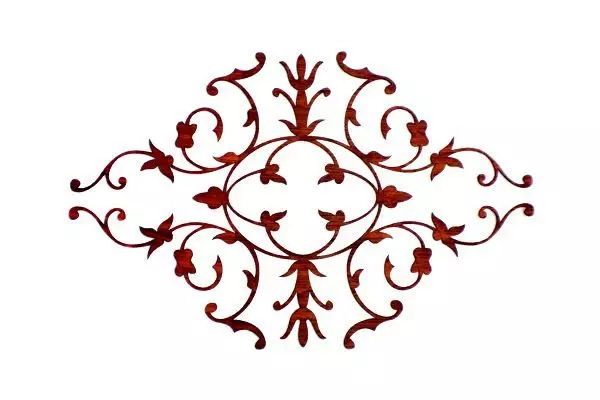

Whether you’re looking for laser cut signs, labels or displays for your business, you can be assured that our results are truly second to none. View the products gallery below to see just what we can do for you, especially when combined with our laser engraving service.

Hit the button and tell us about your next project for your free quote.

LET'S GET STARTED

Our number one focus when producing your laser cut displays, labels and other engraved signs is always surface and edge quality, which is why all of our machines are equipped with one of the world’s best and most trusted brands of laser tubes. We offer one of the largest local laser cutting bed sizes available for sensitive materials such as thin plastics and fabric which cannot be processed on other types of lasers.

Our state-of-the-art precision laser cutting machines allow us to successfully process an array of intricate and precise parts with amazing results; we can accommodate all quantities, from unique one-off items and prototypes to large production runs on an ongoing basis. We also provide laser etching and engraving services.

When you need the highest quality laser cutting services for your laser cut labels and other business requirements, get in touch with Vector & Raster Laser Services today. Request a quote online or give us a call at (03) 5783 4257.

Hit the button and tell us about your next project for your free quote.

About Us

When it comes to our Melbourne laser cutting service, we pride ourselves on high-quality workmanship. Our philosophy is simple, with all things laser cutting and laser engraving, we provide top quality results and customer service that simply rocks! Our Melbourne based laser cutters can be used for a wide range of applications. For added convenience, we also offer online laser cutting services, making it easy to upload your designs and get precision results from anywhere.

Can I have a quote over the phone?

Sorry, but we cannot provide a quote over the phone, laser cutting and laser engraving prices can vary dramatically based on the design and material being processed, we require artwork to provide an accurate quote.

Can you create the correct artwork for me?

Yes, if you are unable to provide the required artwork for processing your order we can create the files for you no matter what process you intend on using whether it be laser cutting or laser engraving.

What type of files do you require?

We require a vector file which has been created in a graphics program, acceptable types include eps, cdr, ai, dxf, dwg and pdf. Cut lines should consist of a red outline with no fill using a .001mm stroke width, areas to be engraved should be in black fill. Only photographs will be accepted as a high resolution jpeg or bitmap.

Can I supply my own materials?

Yes, if you prefer to supply your own materials we are happy to process them for you providing that they are suited to the laser process, a test sample is recommended for perfect results when processing your order.

What is laser cutting?

Laser cutting is a type of machining that uses a focused beam of light to cut through materials such as wood, plastics, paper, fabric, metals, and more. The laser beam is directed by a computer-controlled system and is used to cut and shape the material to precise specifications. Laser cutting is a fast and accurate method of cutting materials and producing intricate components with a high level of precision. Our services have many advantages, such as high accuracy, repeatability, and speed. Get in touch and set an appointment with Vector & Raster today.

How does laser cutting work?

Laser cutting works by using a focused, high-power beam of light to cut and shape the material. It is a non-contact process, meaning that the material does not come into contact with any other material or tool during the cutting process. The laser beam is generated by an exact laser source, which focuses on the material using a set of mirrors and lenses. It is then moved over the material in the desired shape, using a computer-controlled motion system. The laser then heats up the material to the point of melting or vaporising it, resulting in a precise cut.

Our laser cutting services are highly precise and automated, which makes it a great choice for repetitive manufacturing processes. Furthermore, our cutting machines are equipped with a range of features, such as automated fume extraction, intuitive software and drivers, and high-precision CNC controllers.

How much does laser cutting cost?

The cost of laser cutting depends on a variety of factors, such as the type and thickness of the material being cut, the complexity of the design, and the size of the job. Generally, laser cutting services are relatively affordable and cost-effective, ranging from a few dollars for a small job to several hundred dollars or more for a large job and production runs. Book an appointment at Vector & Raster today or you can learn more about our laser cutting method.

How long does laser cutting take?

The time it takes to laser cut a material depends on the complexity of the design, the size of the job, and the type and thickness of the material. Generally, the time it takes to laser cut a material ranges from a few minutes for a small job to several hours for a large job, or even days for large production runs. If you wish to learn more about the duration of a particular task can take with our services and turnaround times, email or book an appointment with V&R Laser today.

How accurate is laser cutting?

Laser cutting is a very accurate machining process and is capable of producing parts and components with a high level of exactness. Laser cutting produces parts and components with a high level of precision – accuracies of approximately 0.1mm can be achieved on most materials, as the laser beam can be precisely controlled and directed to cut the material with a very high level of accuracy. Through our years of experience, V&R Laser has always ensured our services prioritise high-level precision for the jobs we take on.

Does your laser cutting leave burn marks?

No, laser cutting does not leave burn marks on the material. The laser beam is focused and directed at the material to cut it, not to burn it. The laser beam can cut the material without leaving any burn marks or other damage. There are however some materials that may exhibit a slight discolouration on the cut edge due to the nature of the cutting process, they are by no means burnt though and still very clean cuts. If you have any questions regarding our laser cutting services, please get in touch at info@vr-laser.com.au or book an appointment today.

What type of file do you need for laser cutting?

The overall setup of a file needed for laser cutting services depends on the type of material being cut and the design itself. Typically, the file must be in a vector format, such as EPS, PDF, CDR, DXF, or AI. Depending on the material, the file may be converted to a raster format, such as BMP or JPG for engraving photos, images and some logos.

Hit the button and tell us about your next project for your free quote.